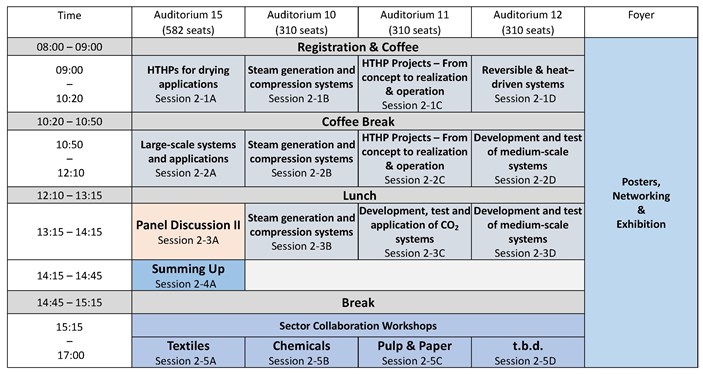

Programme - Day 2

Explore the programme for the second day of the symposium and discover new ways to engage based on your interests.

On the second day, following the main sessions, you will have the chance to join either a sector collaboration workshop - with dedicated tracks on Textiles, Chemicals, and Pulp & Paper. These workshops run in parallel and give you new ways to engage based on your interests.

Get the full overview of what to expect of both days. View the programme for the first day of the symposium.

Explore the programme outline of day 2

Register before 11 January 2026 and secure your seat at the upcoming HTHP Symposium 2026.

Programme - Day 2

08.00 - 09.00 Welcome Back

Networking, coffee and light breakfast

Room: Balcony 1 & 2, first floor

09.00 - 10.20 Individual Sessions

Choose between sessions 2-1A, 2-1B, 2-1C, and 2-1D

HTHPs for Drying Applications

Session 2-1A

Room: Auditorium 15

Chair: t.b.c.

09.00 - 09.20 Optimization of Drying Processes for Integration of Heat Pumps

M. P. Andersen (DTI), C. Tammone(DTI), H. Madsbøll (DTI), J. L. Poulsen (DTI), B. Zühlsdorf (DTI)

09.20 - 09.40 Energy-Efficient Fishmeal Drying Using High-Temperature Heat Pumps

and Superheated Steam

O. Flesland (Pelagia), A. Høeg (Enerin), A. Brækken (SINTEF), P. Verma (Swedish Exergy)

09.40 - 10.00 From Bricks to Boards: Full-Scale Superheated Steam Dryers with High-Temperature

Heat Pumps Commissioned in 2025

C. Nijssen (CEE)

10.00 - 10.20 Scalable and Modular Heat-Pump Drying Systems for Industrial Electrification

M. R. Bøgild (Circular Energy), J. Bendsen (Circular Energy), C. Bay (Circular Energy)

Steam Generation and Compression Systems

Session 2-1B

Room: Auditorium 10

Chair: t.b.c.

09.00 - 09.20 Steam Compressors or Closed-Cycle High Temperature Heat Pump (HTHP)?

– Efficiency and Market-Ready Solutions in Comparison

C. Arpagaus (OST), F. Bless (OST), L. P.M. Brendel (OST), et al.

09.20 - 09.40 Evaluating Steam-Generating Heat Pumps for Industrial Waste Heat Recovery:

Overcoming Technical and Economic Barriers in a Chemical Case Study

N. Pouransari (Syngenta), et al.

09.40 - 10.00 From Waste Heat to Steam: A Case Study on a Process-Integrated MVR Steam

Generating Heat Pump in the Chemical Sector

O. P. Ruiz (Piller), J. Lim (Piller), J. Choong (Piller)

10.00 - 10.20 Steam Generating Heat-Pumps Complemented by Steam Compressors in the Paper

Industry

E. Touliankine (Heatlift), O. P. Ruiz (Piller), et al.

HTHP Projects – From Concept to Realization and Operation

Session 2-1C

Room: Auditorium 11

Chair: t.b.c.

09.00 - 09.20 From Potential to Performance: Integrating High-Temperature Heat Pumps

into Complex Process Industries

A. Arya (PMI), M. Tukker (JOA)

09.20 - 09.40 Advancing High-Temperature Heat Pumps in the Industrial Sector: Challenges,

Innovations, and Implementation Pathways

T. Marren (Astatine)

09.40 - 10.00 From Concept to Installed Reality: Process Integration and Delivery Lessons for

Industrial Heat Pumps

A. Karnik (Ramboll)

10.00 - 10.20 On the Impact of Fluid Property Data on Safety Equipment and Performance

Estimates for High Temperature Heat Pumps

J. Wronski (Clean Heat), K. Fredslund (Clean Heat)

Development and Test of Medium-Scale Systems

Session 2-1D

Room: Auditorium 12

Chair: t.b.c.

09.00 - 09.20 Development of Modular Hydrocarbon-Steam High-Temperature Heat Pumps with

Different Compressor Technologies (MIGHT-HP)

P. J. E. Delêtre (DTI), J. Kristófersson (DTI)

09.20 - 09.40 A Natural-Refrigerant Heat Pump Prototype for Steam Generation above 150°C

M. Ramirez (TNO), G. O. Rodriguez (TNO), R. de Smidt (TNO), U. Timurçin (TNO),

S. Spoelstra (TNO)

09.40 - 10.00 T.b.c.

t.b.c.

10.00 - 10.20 Advancing Air-Sourced High-Temperature Heat Pumps for Industrial Steam

Decarbonization

A. Odukomaiya (AtmosZero), N. Roberts (AtmosZero), W. Arthur-Arhin (AtmosZero), et al.

10.20 - 10.50 COFFEE BREAK

10.50 - 12.10 Individual Sessions

Choose between sessions 2-2A, 2-2B, 2-2C, and 2-2D

Large-Scale Systems and Applications

Session 2-2A

Room: Auditorium 15

Chair: t.b.c.

10.50 - 11.10 Traveling in Time with Atlas Copco: Design and Operational Insights from 40 Years in

Large Heat Pumps

R. Rubycz (Atlas Copco), H. Behnoud (Atlas Copco)

11.10 - 11.30 Testing the World’s Largest CO₂-Based Seawater Heat Pump

Z. Antonini (Everllence)

11.30 - 11.50 HTHP at Berlin City Center: Detailed Test Results and Experiences from Real-World

Operation

G. Balyaligil (KTH, Siemens), S. Sawalha (KTH), J. Schafer (Siemens), K. Moritz (Siemens), et al.

11.50 - 12.10 Thermodynamic Analysis of High-Temperature Heat Pumps and Their Integration

into Geothermal Energy Systems

J. Jeßberger (Uni of Bayreuth), F. Heberle (Uni of Bayreuth), D. Brüggemann (Uni of Bayreuth)

Steam Generation and Compression Systems

Session 2-2B

Room: Auditorium 10

Chair: t.b.c.

10.50 - 11.10 AHEAD - Pioneering CO₂-Free Steam Without Gas Challenges and Experiences in

Producing Chilled Water (6°C), Heating Water (70°C), and Steam (184°C) with

Natural Refrigerants

H. Erös (Takeda), D. Hofbauer (Takeda), et al.

11.10 - 11.30 Waste Heat Upcycling from Superheated Steam Dryer by High-Efficient HTHP with

Cycle Fluid Steam R718

B. Feuerriegel (Lübbers)

11.30 - 11.50 R718 Heat Pump for Efficient Supply of 4.4 MW Steam: Insight and First-Hand

Experience

M. Bantle (Aneo), C. Schlemminger (Aneo), K. Evenmo (Epcon), C. I. Gotaas (Epcon)

11.50 - 12.10 Steam Generating Heat Pump at Pharmaceutical Plant

A. Høeg (Enerin), K. Løver (Enerin), I. Fløystøl (GE Healthcare)

HTHP Projects – From Concept to Realization and Operation

Session 2-2C

Room: Auditorium 11

Chair: t.b.c.

10.50 - 11.10 Development and Integration of Steam Producing High-temperature Heat Pump in

the Sugar Industry

J. L. Poulsen (DTI), E. N. Pedersen (DTI), O. Fredrich (GEA), B. Aerts (Tiense)

11.10 - 11.30 SPIRIT Demo Case I: Full-Scale On-Site Demonstration of a Cascade Industrial Heat

Pump producing steam at 145 °C

G. O. Rodriguez (TNO), W. de Vries (TNO), M. Ramirez (TNO), et al.

11.30 - 11.50 Solution Examples for Cooling and Process Heating in Industrial Applications

I. Rangelov (Danfoss)

11.50 - 12.10 Flexible heat sources while generating process steam above 150 °C – results from the

“Decarbonization of European Dairy industry” project

K. Högnabba (Åbo Uni), T.M. Tveit (Åbo Uni, Olvondo), et al.

Development and Test of Medium-Scale Systems

Session 2-2D

Room: Auditorium 12

Chair: t.b.c.

10.50 - 11.10 Experimental Study on Optimizing Energy Efficiency in a Steam-Producing Heat

Pump System with Waste Heat Recovery

M. Enge (TUDresden), T. Werner Moesch (Combitherm), K. Klotsche (TU-Dresden),

C. Thomas (TU-Dresden)

11.10 - 11.30 Steam generation with heat upgrade technologies - Laboratory tests

and demonstration in the industry

L. Alonso (TECNALIA), M. G. de Arteche (TECNALIA), et al.

11.30 - 11.50 High-Temperature Butane Heat Pump for the R&D project EcoHeat Revolution

S. Beltman (Dutek)

11.50 - 12.10 Development and testing of cascade HTHPs with hydrocarbons

N. Ahlbrink (DTI), J. L. Poulsen (DTI), B. Zühlsdorf (DTI)

12.10 - 13.15 LUNCH

13.15 - 14.15 Individual Sessions

Choose between sessions 2-3A, 2-3B, 2-3C, and 2-3D

Looking Ahead – Bringing Technologies into Application

Session 2-3A

Room: Auditorium 15

Chair: t.b.c.

13.15 - 14.15 This session will discuss what’s ahead with a focus on how to bring systems into application. Stakeholders with different views on the value chain will share their key takeaways and considerations for future activities.

Participants will be announced shortly.

Steam Generation and Compression Systems

Session 2-3B

Room: Auditorium 10

Chair: t.b.c.

13.15 - 13.35 Development of HTHP based on steam as refrigerant and 4-stage oil free reciprocating compressor

O. M. Moen (SINTEF)

13.35 - 13.55 Development and design of a family of highspeed water based Turbo Compressors for MVR and heat pump applications

M. Weel (WSETURBO), J. Rehn (WSE-TURBO), M. Svanteson (WSE-TURBO)

13.55 - 14.15 Case Study: Development of Skyven’s Arcturus Steam-Generating Heat Pump at an Industrial Facility

J. Saccone (Skyven), J. Strasser (Skyven)

Development, Test and Application of CO2 Systems

Session 2-3C

Room: Auditorium 11

Chair: t.b.c.

13.15 - 13.35 CoBra – A High-Temperature, Load-Flexible Brayton-Cycle Heat Pump Demonstrator

A. P. Tran (DLR), J. Oehler (DLR), F. C. Yücel (DLR), P. Stathopoulos (DLR)

13.35 - 13.55 Reverse Brayton HTHP Application for Drying Processes in the Paper Industry: a Case Study

S. Barberis (Unige), A. Patti (Unige), A. Traverso (Unige)

13.55 - 14.15 Techno-economic analysis of a transcritical CO2 heat pump for a high-temperature drying application

J. Lagarde (SynchroStor), J. Oledzki (SynchroStor), A. Dole (SynchroStor), H. Simpson (SynchroStor)

Reversible and Heat–Driven Systems

Session 2-3D

Room: Auditorium 12

Chair: t.b.c.

13.15 - 13.35 Unlocking Value from Waste Heat: Energy Efficiency & Decarbonization without compromise

T. De Vloo (Qpinch), S. Rousseau (Qpinch)

13.35 - 13.55 Unlocking the potential of absorption heat transformer. The path to de-carbonization of steam generation

D. Gorlovsky (JCI)

13.55 - 14.15 Reversible large-scale heat pumps for district heating applications: First experimental characterization and design of a 200 kWel demonstrator

C. Schifflechner (TUM), A. Passamonti (TUM), et al.

14.15 - 14.45 Summing Up (All)

Session 2-4A

Room: Auditorium 15

Chair: B. Zühlendorf, Danish Technological Institute

14.15 - 14.45 This session will summarize the key takeaways from the Symposium and provide an outlook for the next years.

14.45 - 15.15 COFFEE BREAK

15.15 - 17.00 Sector Collaboration Workshops

Choose between sessions 2-5A, 2-5B, and 2-5C

These workshops will focus on bringing all players for the specific sector together for discussing sector-specific solutions. The sector collaborations are organized as part of the IEA HPT Project 68 and are open for all participants.

Textiles

Session 2-5A

Room: Auditorium 15

Chair: S. Pathiraja, Danish Technological Institute

14.45 - 17.00 The session will feature presentations on the overall structure of the textiles sector and their decarbonization targets and supply chain dynamics, as well as technical solutions. Moreover, it will be discussed how to bring solutions into application most optimally.

Chemicals

Session 2-5B

Room: Auditorium 10

Chair: F. Ahrendts, Fraunhofer IEG

14.45 - 17.00 This session will give an overview of the most promising heat pump applications in the chemical sector and discuss options for exploiting the potential.

Pulp and Paper

Session 2-5C

Room: Auditorium 11

Chair: P. Stathopoulos, DLR

14.45 - 17.00 This session provides an overview of the most optimal integration concepts for typical plant layouts and discusses what’s missing to enable complete decarbonization of pulp and paper plants.